麦当劳薯条扒皮:都使用了哪些添加剂?

“谢天谢地!土豆,是个好的开始,”前《流言终结者》主持人格兰特·今原在他继续公布了麦当劳简陋的炸食品里包含的其他13种配料时说道。

The TV personality traveled to the fast food chain's potato processing plant in Idaho to see the production process from start to finish.

这名电视主持人来到了这位连锁快餐大亨位于爱达荷的土豆加工厂,亲眼目睹了食物从开始到结束的生产过程。

During his investigation he found that there are two rounds of frying.

在他的调查期间,他发现薯条要炸两次。

He also discovered that dimethylpolysiloxane - a form of silicone found in Silly Putty - is used in the making of McDonald's fries along with a petrol-based chemical called tertiary butylhydroquinone (TBHQ).

他也发现了用于麦当劳炸薯条的一种橡皮泥里的硅橡胶成分,还有一种名为丁基氢醌的汽油类的化学品。

However, he reassures viewers that these are both safe additives used for perfectly good reasons.

不过,他也打消了观众的疑虑——这两种都是出于做出更完美食物的理由而添加的安全添加剂。

Dimethylpolysiloxane, is added for safety reasons to prevent cooking oil from foaming.

二甲聚硅氧烷是出于安全理由而添加的,为了防止食用油起泡。

While butylhydroquinone (TBHQ) is applied as a food preservative.

不过丁基氢醌是被当做食品防腐剂而用的。

Imahara explains that there are numerous steps involved in the creation of McDonald's fries.

今原解释道,麦当劳炸薯条的诞生包含了一长串步骤。

First potatoes are harvested from fields before being peeled, cut and blanched.

首先,土豆在剥皮,切割和热溶之前从地里被收割起。

They're then fired through a cutter at up to 70 miles an hour into thin sticks.

接着它们被切割机以70英里/小时的速度被切成细条。

After being chiseled into the perfect shape, the strips of potato are sauced with a blend of canola oil, soybean oil, hydrogenated soybean oil, natural beef flavor, hydrolyzed wheat, hydrolyzed milk, citric acid and dimethylpolysiloxane.

被凿刻成完美的形状之后,土豆条加入菜籽油、大豆油、氢化大豆油、天然牛肉香料、水解小麦、水解奶、柠檬酸和二甲聚硅氧烷的混合物调味。

Dextrose - a natural sugar - is sprayed on the batons to help them maintain a golden fried color.Sodium acid pyrophosphate is also added to prevent the fries from going grey.

葡萄糖——一种天然的糖分——被喷在薯条棒上,帮它们保持金灿灿的油炸色。也加入了酸式焦磷酸钠,为了防止炸薯条变老。

Last but not least, salt is sprinkled on for flavor.

最后,撒上盐调味。

The fries are then flash frozen at the Simplot factory and transported to McDonald's outlets across the country.

薯条虽然很快放到毕普芳工厂冰冻起来,并派送到全国的各个麦当劳销售店。

Once they are at restaurants, the potato sticks are fried for a second time.

一旦它们抵达餐馆,薯条就要炸第二次。

The oil blend is similar to the factory mix, with the addition of tertiary butylhydroquinone and hydrogenated soybean oil - a manufactured form of trans fat.

混合油和工厂里的混合很像,不过加入了第三种丁基氢醌和一种转化脂肪氢化大豆油加工剂。

And voila! McDonald's World Famous Fries are served.

然后那!就!是!世界闻名的麦当劳薯条,上餐啦!

[责任编辑:]

相关阅读

- (2015-01-26)美麦当劳薯条疑含硅胶石化物 制作中加入14种化学添加剂

- (2014-06-18)莫让食品添加剂背黑锅

- (2014-06-18)清水加添加剂变鲜果汁 添加剂兑出麻辣烫汤料

- (2014-06-18)中国调整含铝添加剂使用 预估居民摄入量下降85.6%

- (2014-06-18)高档婴儿配方奶粉含40种以上食品添加剂 院士表示很正常

盒装水果省事不卫生 实验解释3大疑问

盒装水果省事不卫生 实验解释3大疑问

“食安中国网”手机站上线通知

“食安中国网”手机站上线通知

食安中国网关于2015年春节放假的通知

食安中国网关于2015年春节放假的通知

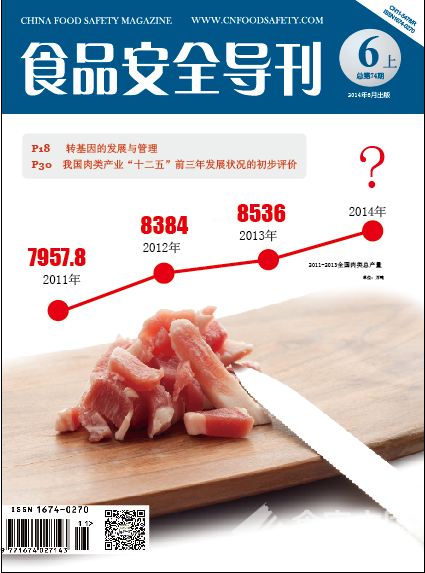

【杂志订阅】《食品安全导刊》杂志订阅优惠活动

【杂志订阅】《食品安全导刊》杂志订阅优惠活动

《食品安全导刊》杂志2015年征订开始

《食品安全导刊》杂志2015年征订开始

扫“食安中国”官方微信,送《食品安全导刊》杂志

扫“食安中国”官方微信,送《食品安全导刊》杂志

IFFA全球肉制品行业翘首以盼的舞台

IFFA全球肉制品行业翘首以盼的舞台

林德与天青水秀的未来中国

林德与天青水秀的未来中国

智能商超方案助力商超节能降本新常态

智能商超方案助力商超节能降本新常态

中国国际食品安全与质量控制会议暨展览在京召开

中国国际食品安全与质量控制会议暨展览在京召开

【绿色和平】果蔬双城记:两座城市的“一日三餐”

【绿色和平】果蔬双城记:两座城市的“一日三餐”

参与评论